Airklarr

Start of safe compressed air management

Safely protect compressed air from microorganisms and germs.

Antibacterial coated interior with negative ion technology to prevent microbial growth

Helps keep you clean by blocking bacterial growth.

Antibacterial coating considering hygiene

cleaner, cleaner

-

Inhibits microbial growth and eliminates 99.9%

Antibacterial coating available -

No element, no maintenance

No need, low differential pressure -

Preparing for HACCP certification and hygiene inspection

Issuance of self-certificate -

Removes more than 99.9997% of condensate

(ISO 12500-4 certified) -

Moisture, oil, even particles

separate at the same time -

Automatically foreign body

(condensate) discharge -

Dissolution standard report

(heavy metal not detected) -

Strong aluminum die-cast case No breakage or corrosion

-

for manufacturers

HACCP certified custom filterDirect and indirect spraying throughout food manufacturing

General area, cleaning area, clean area available -

for safe dental care

Easy and convenient compressed air managementClean compressed air used in medical treatment

Perfect response to the American Dental Association (ADA) 『Dental Compressed Air Quality Regulation』

Prevention of aging, deformation and corrosion of medical tools due to moisture in compressed air

(3-Way Syringe, handpiece, etc.)

Hygienic filter cover

A weak Nobel powder coating applied with anion technology of Blo Cote, a global antibacterial company, is applied to the surface of the product. You can use it with confidence without having to clean or maintain it every time.

(Microbial growth inhibition and 99.9% removable antibacterial coating)

Staphylococcus aureus, Escherichia coli 99.9% removal (JIS Z 2801 : 2010, FITI Testing & Research Institute)

After contaminating a sample (5cm x 5cm) of the same material as HA03 with bacteria, it was confirmed that 99.9% of the bacteria were removed after 24 hours at a temperature of 35℃ and a humidity of 90%.

- antibacterial coating

- anodizing

- aluminum

- antibacterial coating

-

-

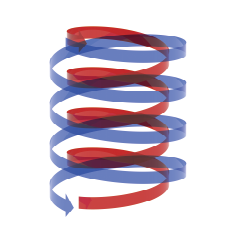

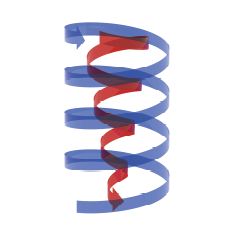

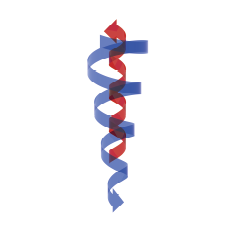

With serial multi-cyclone structure

3,400,000 times stronger than gravityTandem Cyclone™

Powerful rotation accelerating up to 3,400,000G makes fine

Serial multiple cyclones to separate particles, oil, and fine water99.9997%

moisture removal3,400,000G

torque

With two mighty cyclones

Clean the air, clean, more clean

-

01

01Large foreign matter, moisture

1st cyclone separating

-

02

02Gradually gathering particles

external cyclone accelerating

-

03

03Particles, oil and micro-moisture

2nd cyclone to separate

-

04

04Keep rotation until the end to

Internal cyclone to improve separation performance

The world's most powerful

filter without filter

-

No internal element replacement required

Reduction of maintenance cost and easy management -

No risk of cross-contamination from elements

to the environment inside the filter There are no contaminants inhibition of microbial growth -

energy saving filter

There is no element causing differential pressure Less pressure loss than other filters

AUTO DRAIN

You can choose from three convenient drain types to suit your usage environment.

-

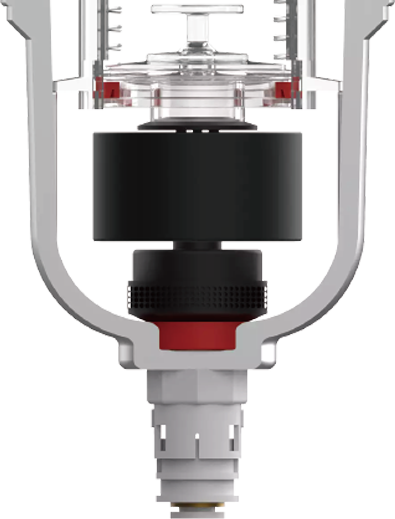

floater type

The floater type uses a swim bladder, and when the water rises above a certain level, This is an automatic way to drain water. This is the most widely used method and is suitable for environments with a lot of moisture. -

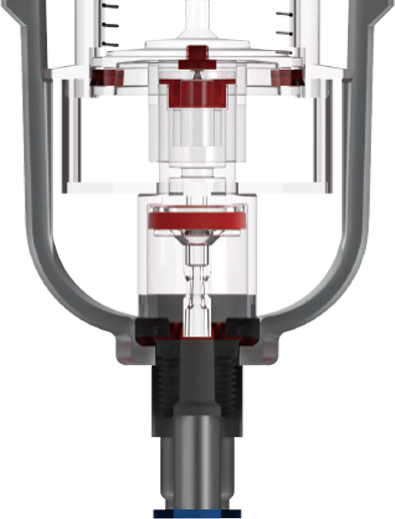

plunger type

The plunger type is a method developed by Teslon and is the first in the world to float on the water level. It is a method of automatically discharging according to the change in flow rate, not by water. This method is suitable for environments with many foreign substances or changes in flow rate. -

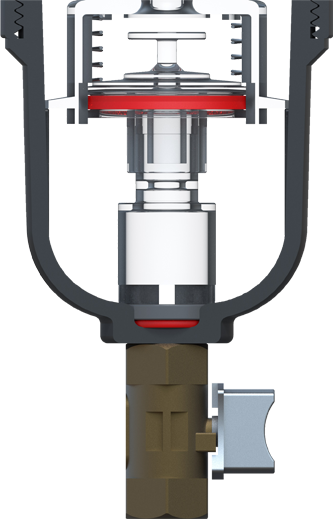

manual type

The manual type is a type in which the internal drain module is completely separated from the outside. Drain replacement is possible without removing the bowl of the body. Therefore, even when the air line is in use, the user can replace the drain at any time. Suitable for environments requiring frequent drain replacement.

Product detailed specifications

-

-

Product specification information

ItemeSeparator, Airklarr

Model nameHA03

Materialaluminum

Maximum flow800ℓ/min

Operating temperature5℃~60℃(41℉~140℉)

Maximum pressure9.9bar (143.6psi)

Differential pressure0.5bar (7.2psi)

Separation methodcentrifugation

Degree of filtrationcondensate 99.9997% / particle 2㎛

Connection size3/8”

Drainautomatic discharge

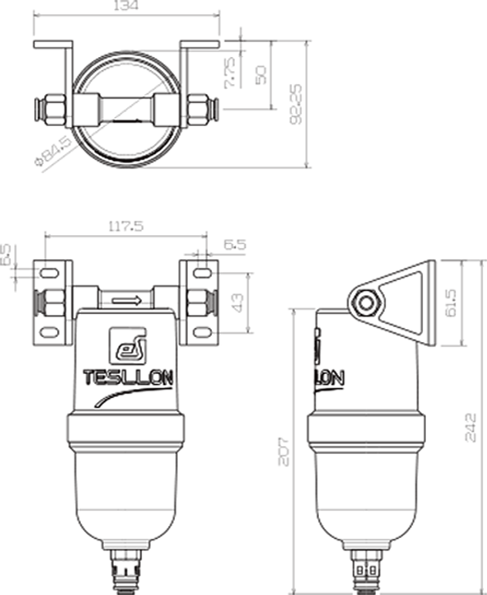

Size85x85x197 (mm)

Warranty1 year

UsageDownload spec sheetUniversal compressed air filter