PAINTING

Fight against moisture, drastically reduce the defect rate

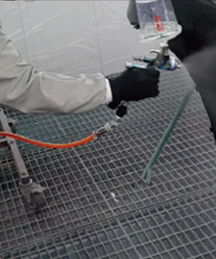

Importance of Compressed Air Filters in Painting

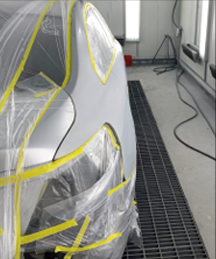

During vehicle maintenance and painting in accordance with the Enforcement Regulations of the Clean Air Conservation Act, oil-based paint cannot be produced and water-soluble paint use is compulsory.

- Mandatory use of oil-based paint as water-based paint (obligatory period 2021.01.01) As the air blowing drying process is added due to the application of water-soluble paint, the importance of removing moisture from compressed air increases↑ Air Quality Conservation Act Enforcement Rule (Ministry of Environment Ordinance No. 866): Mandatory use of water-soluble paint for maintenance and repair painting

In the case of water-soluble painting, it is essential to remove moisture from compressed air, and the drying process is important.

TESLLON compressed air filter

Removes 99.9997% of moistureperfectly.

-

Advantages of using water soluble paint

Excellent gloss/color uniformity Less discoloration and turbidity Excellent adhesion Natural decomposition or eco-friendly ingredients upon evaporation Good coating hardness after drying (compared to oil-based paint) -

Disadvantages of using water-soluble paint

High quality compressed air is required Impossible to commercialize the product when it contains moisture Longer working time (drying time 2 to 3 times) environmental conditions (temperature, humidity, oil, etc.) Sensitive (summer, rainy season, etc. humid environment)

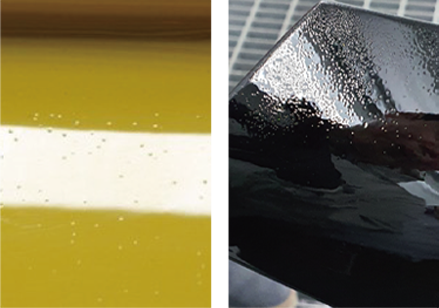

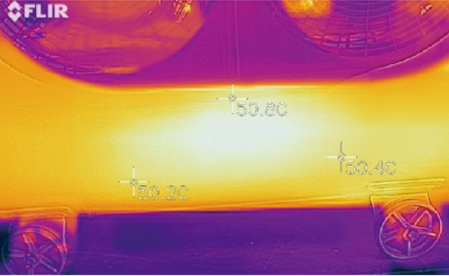

Cases of poor painting when compressed air quality is poor Cratering, blasting (bubbles), etc.

-

Before using the TESLLON eSeparator

-

After using the TESLLON eSeparator

Domestic painting industry supply case

- Used in the practice painting booth of a domestic painting education institution (Polytech University) Used in all-round industries such as furniture, trains, other steel structures, and liquid painting companies that use air spray guns -Substrate adjustment, coloring, filler coating, undercoating, intermediate coating, top coating Painting booth for a first-class automotive industry in Korea

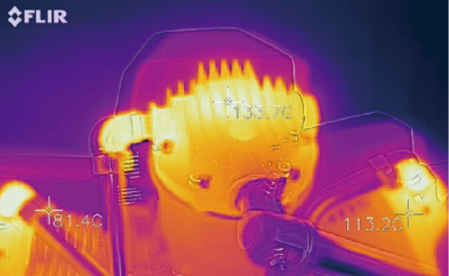

Problems with increased compressor usage

-

water soluble contrast

Increased compressed air usage - water soluble coating : Use 1-3 Air Dry Jets - Increased compressor utilization - Increased heat generation inside the compressor (generates hot air) Humidity 100% in case of rain - Humidity 100% even if it rains in summer (August) - Humidity is 100% even if it rains in winter (December) -

saturated water vapor

Based on the summer temperature of 35℃ - The amount of water vapor contained in each 1㎡ of width x length x height is 40g Based on winter temperature of 10℃ - The amount of water vapor contained in each 1m of horizontal height is 9.3g - About 4 times the frictional area for water vapor - Air at 50°C contains 82 g of saturated water vapor.